Blog

The Ultimate Guide to Designing Eye-Catching PVC Stickers That Stick (Literally!)

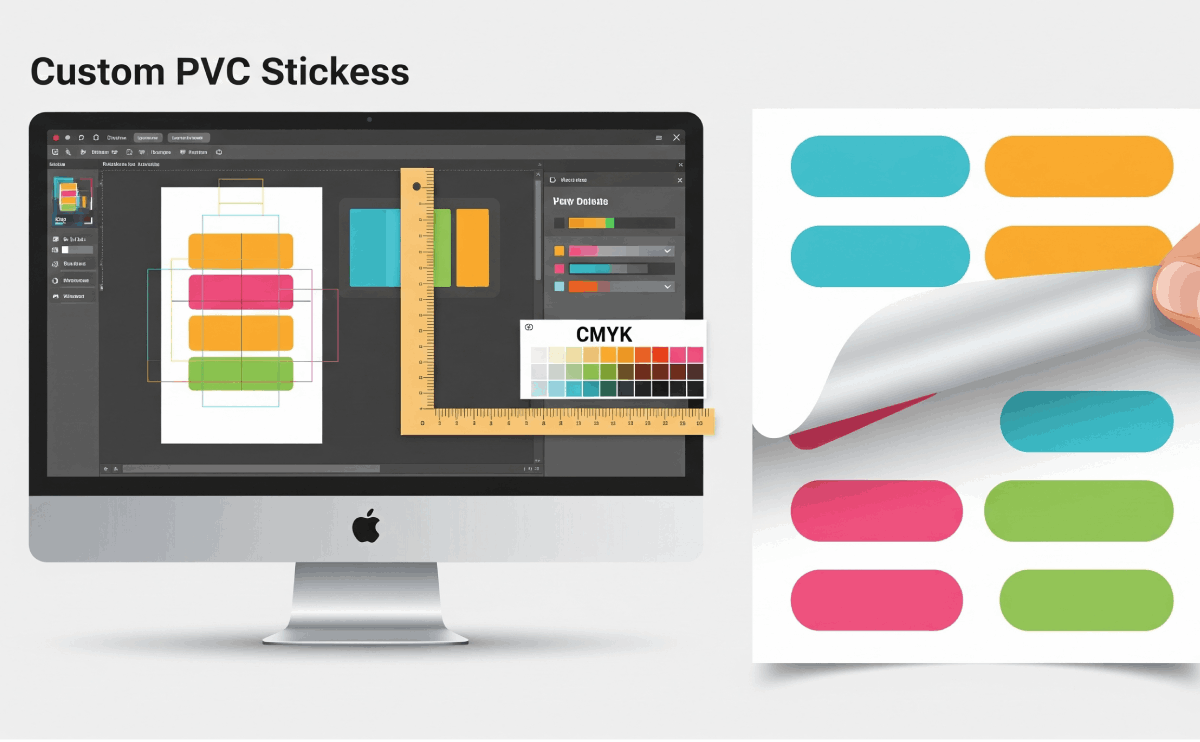

You’ve decided on the unparalleled durability and vibrant quality of PVC sticker printing. Now comes the exciting part: bringing your vision to life through design! But great stickers aren’t just about a good idea; they require careful consideration of design principles, file preparation, and printing specifics to ensure they are both eye-catching and perform flawlessly.

This ultimate guide will walk you through everything you need to know about PVC sticker design, from initial concept to the final, perfectly printed product. Get ready to create custom PVC stickers that not only look fantastic but also “stick” around for the long haul!

Mastering Your Design: Principles for Impact

Before you even open your design software, consider these core principles for eye-catching PVC stickers:

- Clarity is King: Your message or brand logo should be instantly recognizable, even at a glance. Avoid clutter.

- Simplicity Often Wins: Complex designs can get lost, especially on smaller stickers. Bold lines and clear contrasts often have more impact.

- Brand Consistency: Ensure your sticker design aligns with your overall brand identity – colors, fonts, and style should be cohesive.

- Target Audience: Who are these stickers for? Design with their preferences and potential uses in mind. A professional business logo will differ from a quirky band sticker.

- Size Matters: The final size of your sticker will dictate the level of detail you can include. Design at actual size or larger.

Essential File Preparation for PVC Sticker Printing

This is where the magic happens – or where it can go wrong. Proper file setup is critical for high-quality custom PVC stickers.

- Vector Graphics (Preferred): Wherever possible, use vector-based software (like Adobe Illustrator, Inkscape) for logos, text, and sharp graphics. Vector files are scalable to any size without losing quality, ensuring crisp lines.

- High-Resolution Raster Images: If your design includes photos or complex raster elements (from Photoshop), ensure they are at least 300 DPI (dots per inch) at the final print size. Lower resolutions will result in blurry or pixelated stickers.

- CMYK Color Mode: Always design in CMYK (Cyan, Magenta, Yellow, Black) color mode, not RGB. Print presses use CMYK, and designing in RGB can lead to unexpected color shifts when converted.

- Bleed & Safety Margins:

- Bleed: Extend your background colors or images at least 2-3mm beyond the trim line on all sides. This ensures that minor cutting variations don’t result in unwanted white edges.

- Safety Margin: Keep all critical text and logos at least 2-3mm inside the trim line to prevent them from being cut off.

- Outline Fonts: Before sending your file, convert all text to outlines (or curves). This embeds the font data, ensuring your chosen font displays correctly even if the printer doesn’t have it installed.

- Embedded Images: Ensure all linked images in your design file are properly embedded, not just linked. This prevents “missing image” errors.

- File Formats: Common preferred formats include PDF (Press Quality), AI, EPS, or high-res JPG/PNG for simpler designs. Always check with your chosen printer for their specific requirements.

Choosing the Right Cut & Finish

PVC sticker printing offers versatile finishing options that can elevate your design.

- Die-Cut vs. Kiss-Cut vs. Standard Cut:

- Die-Cut: The sticker is cut completely through the backing paper to the exact shape of your design. Ideal for unique, irregular shapes.

- Kiss-Cut: The sticker is cut through the PVC layer but not the backing paper, allowing for easy peeling. Multiple kiss-cut stickers can be on one sheet.

- Standard/Rectangle/Circle Cut: Simple, cost-effective cuts that are easy to produce.

- Lamination Options: A protective laminate layer enhances durability and changes the aesthetic.

- Gloss Lamination: Adds a shiny, reflective finish, making colors pop and providing excellent scratch resistance.

- Matte Lamination: Provides a smooth, non-reflective, sophisticated look. It can slightly mute colors but offers a premium feel.

- Specialty Laminates (if offered): Some printers offer textured, glitter, or holographic laminates for unique effects.

- Adhesive Types: Consider the intended application.

- Permanent Adhesive: For long-term bonding.

- Removable Adhesive: For temporary applications or when you might want to reposition the sticker.

Proofing: Your Last Chance for Perfection

Never skip the proofing stage!

- Digital Proof: Your printer will typically send a digital proof. Review it meticulously for:

- Spelling and Grammar: Typos are easily missed.

- Color Accuracy: Colors might look slightly different on screen than in print; understand these variances.

- Cut Lines & Margins: Ensure everything is within the safe zones and the cut line is accurate.

- Overall Layout: Does it look balanced and professional?

- Physical Proof (if critical): For very large orders or highly color-sensitive projects, consider requesting a physical sample to approve before the full run.

Design for Impact, Print for Durability

Designing exceptional PVC stickers is a blend of creative vision and technical precision. By understanding fundamental design principles, preparing your artwork meticulously, and selecting the right finishes, you can ensure your custom PVC stickers not only grab attention but also withstand the test of time and elements.

Don’t let your brilliant ideas be undermined by poor print quality or an inadequate material. Invest in professional PVC sticker printing and let your designs truly stick!